Modern factories now use robotics, artificial intelligence, and smart control systems. This mix, called automation engineering technology, makes production faster and more accurate. It also cuts down on mistakes and waste.

This field is key to Industry 4.0. Smart machines talk to each other in assembly lines. In car and drug factories, these systems do tasks that humans used to do. Now, people can focus on checking quality and improving systems.

New tech is making factories smarter. Machines can predict when they might break down. Robots work with people, making tasks easier and safer. These changes help factories work better and use resources wisely.

These technologies work together to make factories run themselves. They use data to make changes quickly. This keeps products the same quality. Companies that use industrial automation systems can be faster, bigger, and more sustainable.

Defining Automation Engineering Technology

Automation engineering technology is key to modern industries. It combines new hardware with smart software. This field creates systems that work on their own, needing less human help and improving accuracy in making things.

Core Principles and Scope

Three main ideas shape good automation plans:

- System unification: Connecting mechanical, electrical, and digital parts smoothly

- Process optimisation: Making production better by analysing data

- Adaptive control: Changing things in real time based on what sensors say and how well things are working

These ideas help make products more consistent, which is great for making lots of things like gadgets. A Samsung manager said:

“Our automated assembly lines now complete 47% more units per shift compared to manual operations.”

Key Components in Modern Systems

Today’s automation systems use three main technologies:

Programmable Logic Controllers (PLCs)

PLCs are the brain of industrial automation, doing tasks fast and accurately. Big car factories use them to:

- Sync up robotic arms for welding

- Keep an eye on conveyor belt speeds

- Start checks for quality

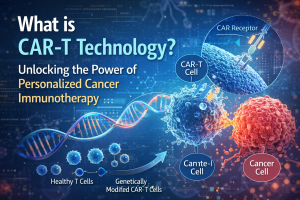

Industrial Robotics Integration

Factories now use 6-axis robots for very precise tasks. BMW’s Spartanburg plant shows this with:

- Automated stations for building car chassis

- Robots working with people

- AI for spotting mistakes

Machine Vision Technology

Advanced cameras can check quality fast, something people can’t do. Foxconn’s phone lines use:

- High-res CCD cameras

- AI to find defects

- Feedback for aligning parts

This tech cut down on recalls by 62% in 2023, Foxconn reports.

Strategic Benefits for Manufacturing Operations

Modern manufacturers use automation to get big benefits. These systems improve output efficiency, product consistency, and employee protection. By using smart tech, companies can stand out and stay ahead.

Productivity Enhancement Metrics

Automated lines run 92% of the time, compared to 68% for manual ones. This means they work non-stop, making more without needing more people. Here are some key numbers:

- Automotive assembly is 45% faster with automation.

- Machine idle times drop by 63%.

- Investment in automation pays back 12 times in 18 months.

| Metric | Manual Process | Automated System |

|---|---|---|

| Units/hour | 120 | 290 |

| Error rate | 8.2% | 0.9% |

| Overtime costs | £18,500/month | £2,100/month |

Quality Control Improvements

Advanced automated quality assurance finds problems 400% faster than people. A recent study in the automotive sector showed:

“AI visual inspection cut welding defects by 37% in six months, saving £2.3 million in recall risks.”

This accuracy comes from machine learning looking at 5,000 data points per part. This is more than the 12 points humans check. It also means less waste during production.

Workplace Safety Advancements

Robots handling dangerous materials cut injury rates by 81% in chemical plants. Modern industrial safety systems include:

- Predictive collision avoidance sensors

- Remote equipment monitoring

- Automated emergency shutdown protocols

These systems make workplaces safer while keeping production high. This is key in risky areas like metal work and pharma.

Implementation Challenges and Solutions

Bringing in automation engineering tech comes with big hurdles. We need to focus on three main areas: getting the workforce ready, keeping systems safe from cyber threats, and updating old infrastructure. Overcoming these challenges is key to a smooth digital changeover or avoiding big problems.

Workforce Adaptation Strategies

Workforce reskilling programmes are essential for tech adoption success. Studies show that mixing classroom learning with virtual reality boosts success by 40%. Good strategies include:

- Creating flexible upskilling paths for different roles

- Training IT and engineering teams together

- Working with tech schools for certification programs

| Approach | Traditional Method | Modern Solution | Impact |

|---|---|---|---|

| Skill Development | Generic workshops | AI-powered learning platforms | 63% faster competency gain |

| Knowledge Retention | Paper manuals | Interactive digital twins | 41% improvement |

| Certification | Annual assessments | Micro-credential systems | 89% compliance rates |

Cybersecurity Considerations

Today’s industrial cybersecurity measures go beyond just firewalls. With more connected systems, we need zero-trust setups with:

- Biometric access controls for both physical and digital spaces

- Algorithms that spot anomalies in real-time

- Encrypted data flows between old and new systems

“Companies with multi-layered security cut breach risks by 78% compared to old methods.”

System Integration Complexities

Legacy system integration is a big challenge, with 62% of companies facing compatibility issues. Solutions include:

- Middleware platforms that translate between old and new systems

- API gateways for safe data sharing

- Phased updates to avoid downtime

New integration tools cut down on setup time by 33% and keep production going. These tools are a big help for companies with equipment from different eras.

Industry 4.0 Applications

Manufacturing is changing fast with Industry 4.0 technologies. These technologies mix physical and digital systems. This makes factories run better, predict problems, and test processes before they start.

Smart Factory Deployments

Smart factory IoT networks connect sensors to watch over everything. BMW uses data to tweak robots just in time. This cuts down waste by 18% and keeps production perfect.

Predictive Maintenance Systems

Predictive maintenance AI looks at machine data to prevent breakdowns. A US aerospace company saw 23% less downtime. This saves £140,000 a year on repairs.

Digital Twin Implementations

Siemens’ Amberg Electronics Plant shows the power of digital twin simulations. They test 47 ways to improve production every hour. This boosts output by 14% and keeps products reliable.

Industry 4.0 is real and making factories better. It lets them predict and solve problems quickly.

Emerging Technological Frontiers

Manufacturing is changing fast, thanks to three key technologies. These include self-optimising assembly lines and human-robot teamwork. They help solve problems like making things faster, more flexible, and making decisions quicker.

AI-Driven Process Optimisation

BMW’s neural networks show how AI can improve manufacturing. Their Munich plant uses AI to adjust production plans based on many factors. This includes supplier delays and tool availability.

They’ve seen a 23% drop in downtime compared to old methods. This is thanks to AI’s ability to adapt quickly.

Here’s how they did it:

- They added sensors to production assets.

- They trained deep learning to recognise patterns.

- They set up feedback loops with ERP systems.

Cobotics Workforce Integration

Boston Scientific’s work with cobot-assisted assembly shows the power of robotics and humans working together. Their machines can place tiny parts with 0.9μm accuracy. Workers can now manage three stations at once, not just one.

| Metric | Traditional Robotics | Cobotics |

|---|---|---|

| Setup Time | 42 hours | 9 hours |

| Space Requirements | 12m² per cell | 4m² per unit |

| Human Interaction | Safety barriers required | Direct collaboration |

Edge Computing Architectures

Foxconn uses edge computing to handle 2.7TB of quality control data every hour. This cuts down on cloud delays, reducing defective units by 18%. They make adjustments right away.

Their system combines:

- On-premise edge nodes for urgent tasks

- Fog computing for regional analysis

- Cloud for long-term trends

This setup saved £412,000 a year in data costs. It also kept their systems running at 99.97% uptime.

Workforce Development Requirements

The fast change in Industry 4.0 means we need a workforce ready for new tech. Manufacturers focus on three main areas: training, certifications, and learning systems that adapt.

Essential Technical Competencies

Today’s automation jobs need skills in PLC programming, robotic checks, and IIoT management. Siemens and Rockwell Automation offer training in digital twins and data analytics for maintenance.

Skills like cybersecurity, machine learning, and SCADA operation are key, according to recent studies.

Certification Pathways

Courses like mechanical engineering technology-robotics and automation offer clear standards for skills. Top choices include:

| Provider | Focus Area | Duration |

|---|---|---|

| Rockwell Automation | Smart manufacturing systems | 6-9 months |

| Siemens Tech Academy | Digital factory integration | 12 months |

Continuous Learning Frameworks

With 73% of manufacturers facing skills obsolescence in 18 months, ongoing learning is vital. Microlearning and academy partnerships offer:

- Monthly skills refresh modules

- Augmented reality-assisted training

- Cross-functional team upskilling

Top companies spend 12-15% of their budgets on training. They know that adapting to new tech is key to success.

Conclusion

Automation engineering is key to modern industry success, boosting efficiency worldwide. Companies using PLC-based control systems see 23% more production and pay back in 18 months. This shows the value of investing in automation.

Today’s production needs to be quick and flexible to meet changing market needs. Automation helps achieve this by making production more agile and scalable.

Now, sustainable production cuts energy use by 40% with smart sensors and AI. Companies like Siemens and Rockwell Automation show how to reduce waste and keep quality high. This is good for the planet and keeps production efficient.

Automation is also key to the circular economy, focusing on both efficiency and being green.

Using predictive maintenance and digital twins makes production more reliable. Edge computing helps make quick decisions at the machine level. This balances customisation with keeping inventory lean.

Upskilling workers is important as automation gets more complex. This keeps human skills at the heart of managing advanced production systems.

Companies that adopt automation wisely stay ahead in the market. They use scalable solutions from Honeywell and Emerson to stay competitive. This prepares them for future challenges.

Intelligent, responsive production systems are the future. They are built to handle tomorrow’s problems.

FAQ

How does automation engineering technology drive Industry 4.0 initiatives?

Automation engineering is key to Industry 4.0. It brings together cyber-physical systems, IoT, and data analytics. Siemens’ Amberg Electronics Plant shows how digital twins and connected systems improve quality to 99.9988%.

What core components enable precision in automotive manufacturing automation?

Automotive production uses PLCs, robots, and machine vision. BMW’s Leipzig plant uses AI to cut paint shop reworks by 37%.

How do predictive maintenance systems reduce operational downtime?

Predictive maintenance uses sensors and edge computing. Ford’s Cologne plant saw a 23% drop in downtime thanks to early detection of issues.

What cybersecurity measures protect automated production networks?

Companies like Rockwell Automation use zero-trust architectures and encrypted protocols. Their FactoryTalk® Logix Echo platform protects against attacks in sensitive areas.

How are manufacturers addressing legacy system integration challenges?

Schneider Electric’s EcoStruxure middleware helps integrate old and new systems. It cut commissioning time by 40% at TotalEnergies’ Normandy refinery.

What certifications validate automation engineering competencies?

Certifications like Siemens Mechatronic Systems Certification and Rockwell Automation’s PartnerNetwork show expertise. They meet Industry 4.0 standards.

How do collaborative robots enhance medical device manufacturing?

Stryker’s Cork facility uses Universal Robots UR10e cobots for precise assembly. They work safely in cleanrooms, ensuring quality in joint replacement components.

What energy efficiency gains do smart factory implementations deliver?

Foxconn’s Shenzhen campus cut power use by 18% with edge computing. It also recovered 27% of waste heat for heating in winter.